High Strength Friction Grip Bolt

Structure Bolts, Nuts and Washers in Friction Grip Joints

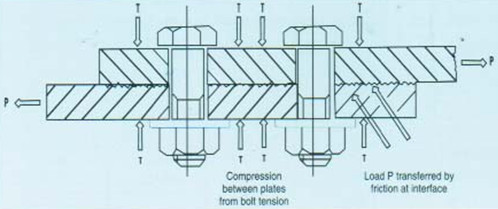

The use of high strength structual fasteners in friction grip joints has been one of the most importnat developments in structural engineering over the last four decades. It provides a simple method of transmitting loads through a structural joint by the friction on the contact face developed through the high clamping force from correctly tightened high strength bolts and nuts.

The bolts are fitted in clearnance holes and since the joint is designed to resist slp , they are not subject to bearing or shear forces and thus remain in virtually static tension throughout their working life with fluctuating loads having very little, of any effect on bolt stress.

The head dimensions (across float sizes) of H.S.S. Bolts and Nuts are one step higher than those of the normal hexagon bolts and nuts of the same diameter. The bearing pressure under the head of H.S.S. Bolts will this be necessarily lower than that of the conventional of the hard bolt head into softer structural steel is therefore prevented.

Reliability:

Once tightened, the bolts will remain tight and maintain the permanent strength of the joint. Absence of heavy stress concentration due to absence of bearing between bolts and plates. As bolts are in tension, it does not permit loosening, thus making it most ideal where vibrations are involved.

Economy:

Fewer high strength bolts are required than M.S. bolts and rivets. Drilling of close tolerance holes is not required. Overall weight of the structure will be very light.

Simplicity:

A minimum of skill is required in tightening and the operators need only to follow a few simple rules.

Convenience:

Whether in the workshop or at the site, H.S.S. Bolts enable joints to be made easily. Welding of site splices can be elimnated avoiding the difficulties of welding in adverse weather conditions. Absence of pneumatic hammers used in riveted joints reduce noise level.

| Maximum Permissible Applied Forces for Joints as per IS 4000:1992 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Size of Bolt | Stress Area of Bolt in mm² | Maximum Permissible Applied Forces in Bolts in kN | ||||||

| Tension (P) in Bolts of Preperty Class | Shear in Bearing Type Joints V for Bolts of Property Class | |||||||

| Shank | Thread | 8.8 | 10.9 | 8.8 | 10.9 | |||

| Shank | Thread | Shank | THread | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) |

| M 16 | 201 | 157 | 56.7 | 78 | 40.2 | 31.4 | 52.3 | 40.8 |

| M 20 | 314 | 245 | 88.2 | 122 | 65.2 | 50.8 | 81.6 | 63.7 |

| M 24 | 452 | 353 | 127 | 176 | 93.8 | 73.2 | 117 | 91.8 |

| M 30 | 706 | 561 | 202 | 280 | 146 | 116 | 148 | 146 |

| M 36 | 1017 | 817 | 294 | 407 | 211 | 169 | 264 | 212 |

| Thread Size | M16 | M20 | (M22) | M24 | (M27) | M30 | M36 | |

|---|---|---|---|---|---|---|---|---|

| Pitch | 2.0 | 2.50 | 2.50 | 3.00 | 3.00 | 3.50 | 4.00 | |

| dw | Max. | 16.70 | 20.84 | 22.84 | 24.84 | 27.84 | 30.84 | 37.00 |

| Min. | 15.30 | 19.16 | 21.16 | 23.16 | 26.16 | 29.16 | 35.00 | |

| da | Max. | 18.70 | 23.24 | 25.24 | 27.64 | 30.40 | 33.40 | 39.40 |

| S | Max. | 27.00 | 34.00 | 36.00 | 41.00 | 46.00 | 50.00 | 60.00 |

| Min. | 26.16 | 33.00 | 35.00 | 40.00 | 45.00 | 49.00 | 58.80 | |

| E | Min. | 29.56 | 37.29 | 39.55 | 45.20 | 50.85 | 55.37 | 66.44 |

| K | Max. | 10.75 | 13.40 | 14.90 | 15.90 | 17.90 | 19.57 | 23.55 |

| Min. | 9.25 | 11.60 | 13.10 | 14.10 | 16.10 | 17.65 | 21.45 | |

| N | Min. | 0.60 | 0.80 | 0.80 | 1.00 | 1.20 | 1.20 | 1.50 |

| Maxumum Recommended Tightening Torque Metric Thread for Quality 8.8 | ||

|---|---|---|

| Nominal Thread Dia mm | Course NM | Fine NM |

| M16 | 252 | 268 |

| M18 | 347 | 391 |

| M20 | 492 | 546 |

| M22 | 670 | 736 |

| M24 | 851 | 926 |

| M27 | 935 | 1344 |

| Mechanical Properties of H.S.S. Bolts | |||||||

|---|---|---|---|---|---|---|---|

| Thread Size | Stress Area | Property Class 8.8 | Property Class 10.9 | ||||

| Ultimate Load (Min) | Proof Load (Min) | Hardness | Ultimate Load (Min) | Proof Load (Min) | Hardness | ||

| mm² | Newtons | Newtons | HRC | Newtons | Newtons | HRC | |

| M16 | 157 | 125600 | 91060 | 22-32 | 163280 | 130310 | |

| M20 | 245 | 203350 | 147000 | 23-34 | 254800 | 203350 | |

| (M22) | 303 | 251490 | 181800 | 315120 | 251490 | ||

| M24 | 353 | 292990 | 211800 | 367120 | 292990 | 32-39 | |

| (M27) | 459 | 380970 | 275400 | 477360 | 380970 | ||

| M30 | 561 | 465630 | 336600 | 583440 | 465630 | ||

| M36 | 817 | 678110 | 490200 | 849680 | 678110 | ||

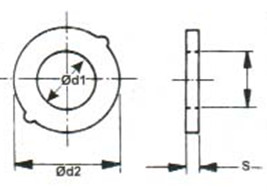

High Strength Structural Washers:

| High Strength Structural Washers - Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bolt Size | M16 | M20 | (M22) | M24 | (M27) | M30 | M36 | |

| d1 | Min. | 18.00 | 22.00 | 24.00 | 26.00 | 30.00 | 33.00 | 39.00 |

| Max. | 18.43 | 22.52 | 24.52 | 26.52 | 30.52 | 33.62 | 39.62 | |

| d2 | Max. | 34.00 | 42.00 | 44.00 | 50.00 | 56.00 | 60.00 | 72.00 |

| Min. | 32.40 | 40.40 | 42.40 | 48.40 | 54.10 | 58.10 | 70.10 | |

| S | Max. | 4.60 | 4.60 | 4.60 | 4.60 | 4.60 | 4.60 | 4.60 |

| Min. | 3.10 | 3.10 | 3.40 | 3.40 | 3.40 | 3.40 | 3.40 | |

| Weight Kg/1000pcs | 20.3 | 31.3 | 33.2 | 44.7 | 54.8 | 61.4 | 89.7 | |

High Strength Structural Nuts:

| High Strength Structural Nuts - Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thread Size | M16 | M20 | (M22) | M24 | (M27) | M30 | M36 | |

| Pitch | 2.0 | 2.50 | 2.50 | 3.00 | 3.00 | 3.50 | 4.00 | |

| W | Max. | 27.00 | 34.00 | 36.00 | 41.00 | 46.00 | 50.00 | 60.00 |

| Min. | 26.16 | 33.00 | 35.00 | 40.00 | 45.00 | 49.00 | 58.80 | |

| C | Min. | 29.56 | 37.29 | 39.55 | 45.20 | 50.86 | 55.37 | 66.44 |

| H | Max. | 17.10 | 20.70 | 23.60 | 24.20 | 27.60 | 30.70 | 36.60 |

| Min. | 16.40 | 19.40 | 22.30 | 22.90 | 26.30 | 29.10 | 35.00 | |

| Weight Kg/1000pcs | 60.4 | 115.3 | 142.8 | 197.7 | 282.3 | 365.0 | 281.8 | |

| Mechanical Properties of H.S.S. Nuts | ||||

|---|---|---|---|---|

| Thread Size | Property Class 8 | Property Class 10 | ||

| Proof Load | Hardness | Proof Load | Hardness | |

| Newtons | Newtons | |||

| M16 | 168900 | HRB 89 to HRC 38 |

195500 | HRB 26 to HRC 38 |

| M20 | 263400 | 305000 | ||

| (M22) | 325700 | 377200 | ||

| M24 | 379500 | 439500 | ||

| (M27) | 493400 | 571500 | ||

| M30 | 603100 | 698400 | ||

| M36 | 878300 | 1017200 | ||

Surecon Fastening

Surecon Fastening Welding Machines

Welding Machines Köco Stud Welding

Köco Stud Welding